Selecting the right metal cable conduit is an essential part of creating electrical installations that are safe, long-lasting, and dependable. Whether you’re upgrading wiring at home or planning a larger commercial project, metal conduits deliver the strength and protection needed to keep cables secure in challenging environments. This guide walks through the different types, where they work best, and how to choose the right option for your installation.

Why Metal Conduits Are a Reliable Choice

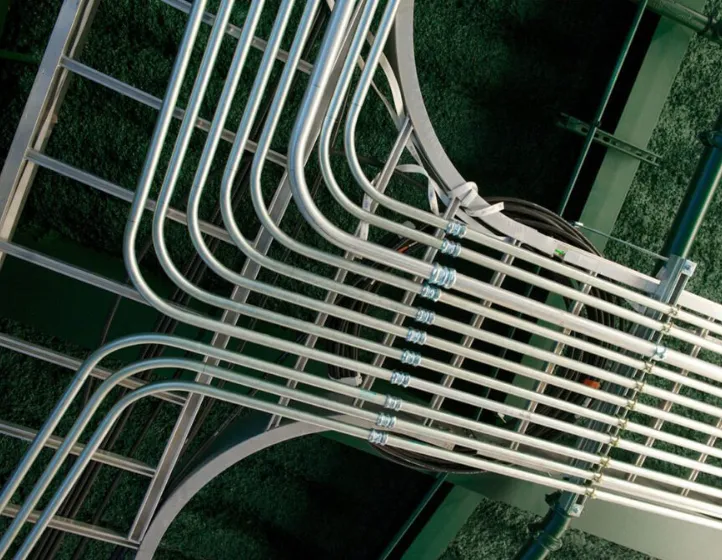

Metal cable conduits are known for their outstanding durability and protective qualities. They’re frequently installed in residential, commercial, and industrial settings because they withstand physical impact far better than non-metallic alternatives. Their rigid construction shields wiring from crushing, abrasion, moisture, temperature extremes, and general wear—making them ideal for demanding or exposed locations.

Built for Tough Conditions

Rigid metal conduit systems, often made from galvanized steel or aluminium, are designed to hold up against harsh environments. They’re especially valued in industrial spaces where chemicals or moisture are present, as galvanised coatings help prevent rust and extend service life.

Natural Grounding Capability

Many metal conduits can act as the grounding path for electrical systems, eliminating the need for separate grounding wires in certain applications. As long as they’re installed correctly and meet regulatory guidelines, this can simplify installation and reduce material use.

Fire and Interference Resistance

Metal conduits also offer protection against fire. Their non-combustible construction adds safety in high-heat areas or locations where fire risk is present. They also help minimise electromagnetic interference, an important benefit in facilities with sensitive electronics, such as medical centres, control rooms, or data networks.

Where Metal Conduits Are Commonly Used

Commercial and Industrial Spaces

In workplaces and industrial facilities, conduits such as intermediate metal conduit (IMC) and electrical metallic tubing (EMT) are widely used. IMC provides strong mechanical protection but is lighter than rigid steel, making it easier to work with. EMT’s thin walls make it suitable for indoor use where wiring is exposed but unlikely to be heavily impacted.

Residential Installations

For homes, EMT is a popular solution for garages, basements, and utility areas. It bends easily and installs quickly, offering a practical balance of protection and convenience. However, it should only be used in dry areas unless sealed appropriately.

Outdoor and Harsh Environments

Liquid-tight flexible metal conduit (LFMC) is the preferred option outdoors or in wet conditions. The waterproof outer jacket prevents moisture ingress, making it ideal for connecting outdoor air conditioners, pumps, and exterior lighting. Stainless steel and aluminium conduits are often chosen in marine or chemical-heavy environments for their superior corrosion resistance.

Understanding the Different Types of Metal Conduit

Rigid Metal Conduit (RMC)

The strongest and most durable option, RMC has thick walls and is often steel or aluminium. It’s suitable for direct burial and harsh outdoor settings. While highly protective, it requires more labour to install due to its weight and threaded connections.

Intermediate Metal Conduit (IMC)

IMC offers a lighter alternative to RMC without sacrificing too much strength. It’s designed to be easier to handle and install while still offering reliable protection, making it a favourite in commercial applications.

Electrical Metallic Tubing (EMT)

Lightweight and easy to bend, EMT is a practical, cost-effective choice for interior wiring. It uses compression or set-screw fittings and is ideal for exposed indoor runs, provided it’s not subject to moisture or physical abuse.

Flexible Metal Conduit (FMC)

FMC is formed from interlocking strips of steel, giving it the ability to bend around corners and machinery. It’s often used to connect fixed conduit to equipment that may move or vibrate, though it’s not rated for wet conditions.

Liquid-Tight Flexible Metal Conduit (LFMC)

LFMC builds on FMC with an added waterproof jacket. This makes it suitable for outdoor installations, areas with oil or moisture, and equipment that needs both protection and flexibility.

How to Select the Right Metal Conduit

Match the Conduit to the Installation Method

Straight, exposed runs may benefit from rigid options like RMC or IMC, while tight corners or machinery connections often require flexible conduits. If the conduit must be buried or encased in concrete, ensure it’s rated specifically for that use.

Assess the Environment

Consider whether your installation area is dry, humid, exposed to chemicals, or prone to impact. Corrosion-resistant materials like stainless steel or aluminium are essential in coastal and industrial areas. LFMC is the best option for wet locations.

Factor in Both Material and Labour Costs

Thicker conduits cost more and require specialised tools. If the project doesn’t require the strength of RMC, IMC or EMT may offer better value without sacrificing safety.

Confirm Code Compliance

Always check local electrical regulations before purchasing. Each conduit type is governed by specific code articles, and installations must meet all applicable standards to ensure safety and avoid rework.

Popular Metal Conduit Options

25mm Galvanised Steel Conduit

A strong and durable choice for rigid installations. Its corrosion-resistant coating makes it suitable indoors and outdoors, and the smooth interior helps with easy wire pulling.

PVC-Coated Flexible Metal Conduit by Deligo

Ideal for areas that require flexibility along with resistance to water and UV exposure. The PVC jacket adds a protective layer against the elements, making this a solid choice for outdoor equipment connections.

Final Thoughts

Metal cable conduits remain one of the most reliable ways to protect electrical wiring in both everyday and demanding environments. By considering installation needs, environmental conditions, and regulatory requirements, you can choose the conduit that ensures safety, longevity, and efficient performance throughout your project.