When planning an outdoor lighting setup or organising electrical equipment in a workshop, one essential component often gets overlooked: the electrical enclosure box. It’s the protective shell that keeps wiring, switches and connections safe from dust, moisture and accidental damage. But with both metal and plastic enclosures available, deciding which style suits your project can be more challenging than it first appears.

Understanding how these enclosures differ—and the benefits each offers—will help you choose the option that keeps your installation protected and running reliably.

What an Electrical Enclosure Box Does

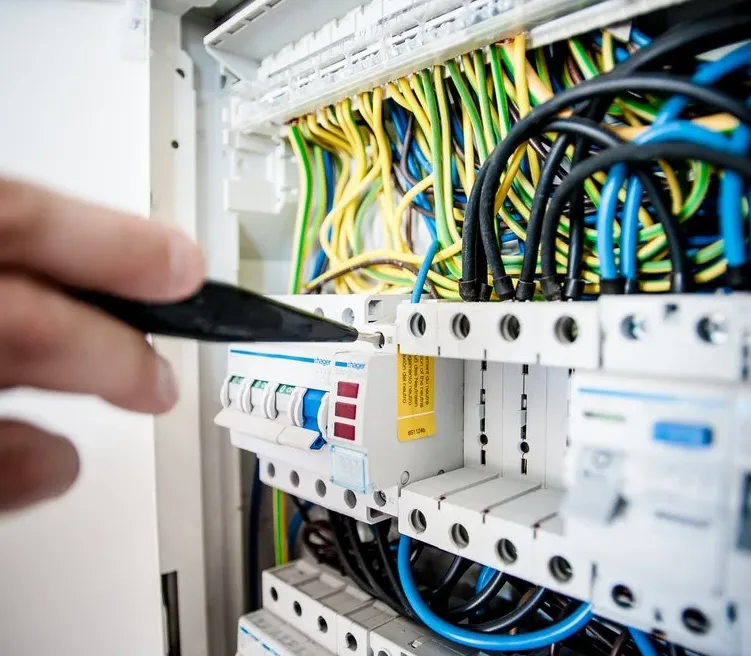

An enclosure box is designed to safeguard electrical components from environmental exposure and physical interference. These boxes often come with an IP (Ingress Protection) rating, which indicates how well they guard against dust and water. For instance, an IP66 enclosure offers full dust protection and withstands powerful water jets, making it suitable for demanding outdoor use.

The two most common materials for enclosure boxes are metal and plastic, each with features that suit particular environments and applications.

Metal Enclosures: Built for Demanding Environments

Metal enclosures, typically made from steel or aluminium, are widely used in industrial settings or locations where durability is essential.

Why Choose Metal?

- Exceptional strength: They tolerate impact, extreme temperatures and harsh operating conditions.

- Enhanced security: Their solid construction provides extra protection in public or high-traffic areas.

- Reduced interference: Metal naturally shields sensitive equipment from electromagnetic disturbances.

- Long service life: With proper care, a metal enclosure can last for many years.

Potential Drawbacks

- Heavier and harder to install: Their weight can make mounting more labour-intensive.

- Higher upfront cost: Construction quality and materials make them more expensive.

- Possible corrosion: Without protective coatings, they may deteriorate in humid or salty environments.

A metal enclosure is the better choice when strength, stability and security are top priorities.

Plastic Enclosures: Lightweight and Practical

Plastic enclosures—commonly made from ABS or polycarbonate—are popular in homes and light commercial setups. They offer reliable protection without the weight or cost of metal.

Why Choose Plastic?

- Lightweight and easy to handle: Installation is simple, particularly in quick retrofit jobs.

- Corrosion-resistant: Ideal for damp areas where metal might rust.

- Affordable: They deliver dependable protection at a lower price point.

- Non-conductive: A safer option when electrical insulation is important.

Things to Consider

- Less impact resistance: They’re durable but not as rugged as metal under heavy stress.

- Aesthetic limitations: Their appearance may not blend well in every setting.

- Vulnerability to sunlight: Some plastics can fade or weaken with prolonged UV exposure.

Plastic enclosures work best for domestic installations or light industrial environments where weight, price and convenience matter most.

Key Factors to Consider When Choosing

The ideal enclosure depends on the specific needs of your project. Here’s what to evaluate:

- Location: Outdoors or exposed areas may require a tougher enclosure; plastic is suitable for dry indoor spaces.

- Application: Heavy machinery and industrial equipment benefit from metal. Smaller residential circuits often suit plastic.

- Budget: Plastic is more economical; metal offers longevity that may reduce long-term costs.

- Ease of installation: Plastic is lighter and easier to mount.

- IP rating: Higher IP ratings (like IP66) provide superior protection, important in harsh environments.

Example Enclosures and Their Uses

- Compact polycarbonate enclosures work well for small garden lighting or minor outdoor circuits.

- High-rated plastic boxes with strong sealing are dependable for more demanding outdoor installations.

- Mid-sized plastic enclosures serve well in garages, patios and workshops.

- Insulated modular enclosures offer flexibility for custom electrical setups.

Making the Right Choice

Choosing between metal and plastic comes down to balancing environment, budget and functional demands. Metal excels in tough conditions where durability is key, while plastic offers a cost-effective solution for lighter, everyday applications.

Whichever material you choose, ensuring the enclosure has the right IP rating and is suited to the environment will keep your electrical system protected and operating safely.