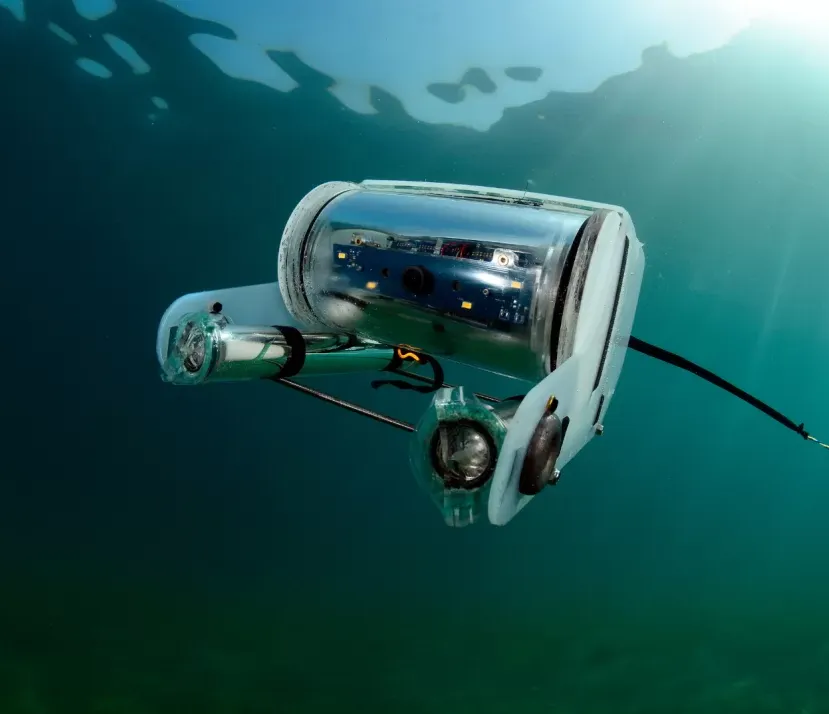

Remotely Operated Vehicles (ROVs) are essential tools for underwater missions—supporting activities such as offshore inspections, subsea construction, and oceanographic research. At the heart of every ROV system lies the tether, the cable that delivers power, control, and data between the vehicle and its surface operator. Despite growing autonomy in modern ROVs, long tethers remain indispensable for deep-sea operations. Managing these extended cables, however, brings a host of technical and operational difficulties. Here are five major challenges faced by engineers and operators—and how emerging innovations are helping to overcome them.

1. Managing Weight and Drag

Long tethers, even when designed to be neutrally buoyant, still create drag as they move through water. The heavier and longer the tether, the greater the resistance it produces. This added drag limits the ROV’s maneuverability, forcing the thrusters to work harder and consume more power, which in turn shortens operational time.

The solution: Modern tethers now use ultra-lightweight, high-strength materials such as aramid fibers and neutrally buoyant jackets. These advances reduce hydrodynamic drag and improve handling. By cutting down on weight and resistance, ROVs can move more efficiently while maintaining stable control, even at great depths.

2. Balancing Strength and Flexibility

ROV tethers must be both strong and supple—capable of withstanding mechanical stress while remaining flexible enough for repeated deployment and retrieval. This balance is critical because cables that are too stiff can kink or break, while overly soft ones can stretch or fatigue over time.

The solution: Hybrid designs incorporating reinforced polymer coatings and flexible strength members help achieve this balance. These tethers combine tensile durability with elasticity, allowing them to bend and spool smoothly without internal damage. The result is longer service life and fewer failures during demanding subsea operations.

3. Maintaining Signal Integrity Over Long Distances

ROVs depend on high-speed communication for navigation, real-time video, and sensor feedback. But as cable length increases, signal loss and power drop become significant problems. Electrical interference and attenuation can degrade data quality or disrupt communication altogether.

The solution: Incorporating fiber optics within hybrid tethers provides a robust answer. Fiber-optic cores allow the transmission of large data volumes with negligible signal loss, even over kilometers. These cables also eliminate electromagnetic interference, ensuring crisp video, accurate telemetry, and reliable control. Integrating both power and data channels in one compact cable has become the industry standard.

4. Handling and Storage

Deploying and retrieving a multi-kilometer tether is no small feat. Poor handling can lead to twists, kinks, or abrasions that compromise cable integrity. Incorrect coiling or over-bending during recovery can cause permanent deformation, putting the entire operation at risk.

The solution: Specialized winches and storage systems with controlled tensioning help prevent damage. Operators use guided reels designed to maintain the cable’s minimum bend radius and prevent uneven winding. Tethers with abrasion-resistant outer jackets further protect against wear caused by repeated spooling and contact with rough deck surfaces.

5. Withstanding Harsh Environmental Conditions

Underwater conditions are unpredictable and harsh. Tethers are constantly exposed to saltwater corrosion, immense pressure, biological growth, and temperature extremes. Over time, these factors can degrade insulation, compromise strength, and lead to complete tether failure.

The solution: Engineers have developed new materials like polyurethane and thermoplastic elastomers that can endure temperature variations and resist saltwater corrosion. Anti-fouling coatings prevent marine organisms from adhering to the cable surface, while sealed, pressure-resistant designs extend operational lifespan in deep-sea environments.

The Rise of Next-Generation Tether Technology

Advancements in tether design are transforming subsea operations. Companies are now producing hybrid cables that combine fiber optics, electrical conductors, and strength members in a single, compact unit. These multi-functional designs minimize overall diameter, improve reliability, and allow ROVs to work deeper and longer with fewer interruptions.

Best Practices for Operators

Even the most advanced tether can fail without proper care. Operators should adopt preventive measures such as:

- Inspecting cables regularly for wear or damage

- Using tension-controlled reels for spooling and retrieval

- Avoiding bends that exceed the manufacturer’s minimum radius

- Cleaning and drying cables thoroughly after saltwater exposure

These practices ensure both performance and longevity in challenging marine conditions.

Conclusion

ROV tethers are the vital link between human operators and the subsea world. Managing them effectively demands a combination of innovative design, durable materials, and disciplined maintenance. By addressing key challenges—weight, flexibility, signal integrity, handling, and environmental resistance—operators can enhance both safety and efficiency in underwater missions. As tether technology continues to evolve, the limits of deep-sea exploration and subsea engineering will only continue to expand.