In an age where data transmission powers everything from defense operations to offshore exploration, ensuring signal reliability under extreme conditions has become a technological necessity. Ruggedized fiber optic cables are the unsung heroes of this challenge—engineered to deliver high-speed communication in places where ordinary cables would fail. Built with advanced materials and precision engineering, these cables merge the delicacy of light transmission with the strength to survive physical and environmental stress.

What Makes a Fiber Cable “Ruggedized”

Unlike standard telecom fibers designed for controlled environments, ruggedized fiber optic cables are built to operate in demanding conditions such as military zones, industrial plants, and subsea installations. These cables must endure mechanical strain, intense vibration, temperature extremes, and exposure to moisture or chemicals—all without compromising performance.

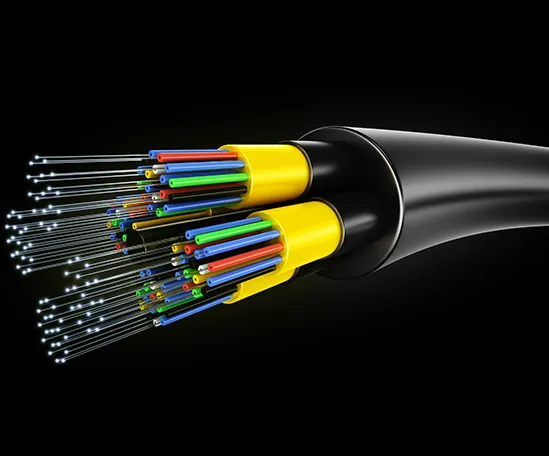

Ruggedized fibers achieve this durability through a layered structure that protects the delicate glass core while maintaining flexibility and optical precision.

The Core Science of Optical Fiber Transmission

At their heart, fiber optic cables rely on total internal reflection to transmit light signals through a core surrounded by cladding. This enables enormous amounts of data to travel at light speed with minimal loss. However, the real challenge lies in keeping this fragile glass pathway intact amid crushing pressure, heat, and movement. Ruggedized cables address this challenge through enhanced coatings, strength members, and specialized jacketing materials.

Anatomy of a Ruggedized Fiber Cable

1. Core and Cladding

The core carries the light signal, while the cladding ensures it stays confined. Both must meet international optical standards like ITU-T or MIL-SPEC. The choice between single-mode and multimode fibers depends on the distance and bandwidth required.

2. Primary Coating

A soft polymer coating cushions the core, absorbing minor shocks and preventing micro-bends that could distort the signal.

3. Strength Members

Materials such as Kevlar or steel wires distribute mechanical load, protecting the fiber from stretching or breaking during handling or deployment.

4. Buffer Tubing

Depending on the application, cables may use tight-buffer or loose-tube construction. Loose-tube designs are favored for outdoor use as they accommodate expansion and contraction in fluctuating temperatures.

5. Outer Jackets and Armor

The final layer provides environmental protection. Polyurethane and PVC jackets offer flexibility and abrasion resistance, while LSZH (low-smoke, zero-halogen) jackets are used in enclosed spaces. In harsh environments, stainless-steel or corrugated armor may be added to prevent crushing or rodent damage.

Engineering for Harsh Conditions

Ruggedized fiber cables must maintain performance in some of the planet’s most punishing environments. Engineers achieve this by optimizing material properties and cable design for specific stress factors.

Temperature Extremes

Cables are formulated with polymers that remain stable from -60°C to over 150°C, ensuring reliable operation from Arctic research bases to jet engines.

Moisture and Chemical Resistance

Water-blocking gels, UV-resistant jackets, and corrosion-proof layers prevent damage from saltwater, humidity, and industrial chemicals.

Mechanical Durability

To survive repeated bending and coiling, these cables undergo crush, tension, and flex tests. They can be deployed across rough terrain or submerged without losing structural integrity.

Testing for Reliability

Before deployment, ruggedized cables are subjected to a series of performance evaluations. These include mechanical stress tests (crush, tension, impact), thermal cycling, and vibration trials based on standards such as IEC 60794 and MIL-STD. They are also tested for ingress protection (IP ratings) and optical attenuation to ensure minimal signal loss under pressure. The result is a cable that maintains high transmission quality, even after exposure to environmental stressors.

Where Ruggedized Fiber Optics Are Used

Military and Tactical Operations

Field-deployable cables link command centers and field units in war zones, maintaining secure communications despite rough handling or exposure to dirt, water, and explosions.

Oil and Gas Exploration

On offshore rigs and desert sites, rugged fibers support drilling control systems, real-time data collection, and seismic monitoring.

Aerospace and Aviation

Aircraft and spacecraft use these fibers for sensor networks and flight control systems, where they must endure vibration, EMI, and temperature swings.

Marine and Subsea Installations

Deep-sea cables resist immense pressure, corrosion, and biological growth, enabling undersea communication and research.

Innovations Shaping the Future of Ruggedized Fiber

New technologies are enhancing the versatility of ruggedized fiber optics:

- Hybrid Designs that integrate power and data transmission within a single cable for compact, multifunctional systems.

- Expanded Beam Connectors that reduce contamination risk by transmitting light through a focused beam rather than direct contact.

- Self-Healing Jackets made from advanced polymers that can repair minor abrasions, extending the operational lifespan.

Selecting the Right Cable for the Job

Choosing the correct ruggedized cable depends on several factors: environmental conditions (temperature, moisture, chemicals), mobility needs (fixed vs. portable), optical type (single-mode or multimode), and required certifications. Collaborating with manufacturers who offer tailored solutions ensures that the cable meets both performance and regulatory requirements.

Conclusion

Ruggedized fiber optic cables represent the perfect blend of science and engineering—combining the precision of optical technology with the resilience needed to thrive in extreme environments. From defense communication to offshore exploration, they ensure uninterrupted, high-speed data transmission where failure is not an option. As industries push further into challenging frontiers, these cables remain the steadfast link keeping operations connected, efficient, and secure.