Setting up a wired network may seem straightforward, but one of the most important decisions you’ll make is selecting the right type of Ethernet cable. Although Ethernet cables look nearly identical on the outside, the material inside the conductors significantly impacts performance, durability, and long-term reliability. The most common comparison is between pure copper cables and CCA (copper-clad aluminum) cables. Understanding their differences will help you choose the best option for your installation.

What Are Pure Copper Ethernet Cables?

Pure copper Ethernet cables use solid copper conductors. Copper is an excellent electrical conductor and has been the preferred choice for professional network installations for decades. These cables meet industry-recognized performance and safety standards and are designed to support consistent, high-quality data transmission.

What Are CCA Ethernet Cables?

CCA cables use aluminum conductors coated with a thin layer of copper. While the outer copper layer provides some conductivity, the aluminum core has higher resistance and lower performance compared to pure copper. CCA cables are often marketed as a cheaper alternative, particularly for large installations where upfront cost is a major concern.

Electrical Performance Differences

Copper outperforms aluminum in all major electrical characteristics:

- Lower electrical resistance

- Better signal transmission over long distances

- Less signal loss and attenuation

Because aluminum has poorer conductivity, CCA cables struggle with high-speed data applications. Over longer distances, CCA can lead to reduced performance, unreliable connections, or network instability—especially in Gigabit and Power over Ethernet (PoE) environments.

PoE Considerations

PoE systems deliver both power and data over the same Ethernet cable. Devices such as security cameras, wireless access points, and VoIP phones rely heavily on stable power delivery.

- Pure copper cables: Handle PoE efficiently, keep heat low, and maintain consistent voltage.

- CCA cables: Generate more heat due to higher resistance, which can damage devices or cause cable failure.

For any PoE installation, pure copper is the recommended—and safest—choice.

Durability and Safety

Copper is flexible, resistant to corrosion, and less prone to breakage. This makes pure copper cables ideal for installations where cables need to be pulled through walls, conduits, or tight spaces.

CCA cables, by contrast:

- Are more brittle and susceptible to breakage

- Are vulnerable to long-term corrosion

- Have reduced lifespan due to dissimilar-metal interaction between copper and aluminum

These issues can create hidden reliability problems over time.

Standards and Compliance

Industry standards such as TIA/EIA-568 require solid copper conductors for structured cabling. Many CCA Ethernet cables do not meet these standards. Using them in commercial or regulated environments can result in:

- Failed inspections

- Voided warranties

- Potential fire or safety risks

Even in residential settings, non-compliant cabling can create long-term performance issues.

Matching Cable Type to Installation Environment

Choosing between copper and CCA depends heavily on the installation environment:

- Long cable runs: Pure copper ensures reliable performance over distances beyond 55–100 meters.

- High-temperature or bundled cable areas: Copper handles heat buildup more effectively.

- In-wall or outdoor use: Copper provides better safety and compliance.

- Temporary or low-demand networks: CCA may be acceptable, though not ideal.

For any permanent or high-demand application, pure copper remains the better option.

Long-Term Value

While CCA cables cost less upfront, they tend to cost more over time due to:

- Higher failure rates

- Poor PoE performance

- Frequent replacements

- Limited support for future network upgrades

Pure copper cables offer better long-term value by delivering consistent performance and reducing the need for maintenance or early replacement.

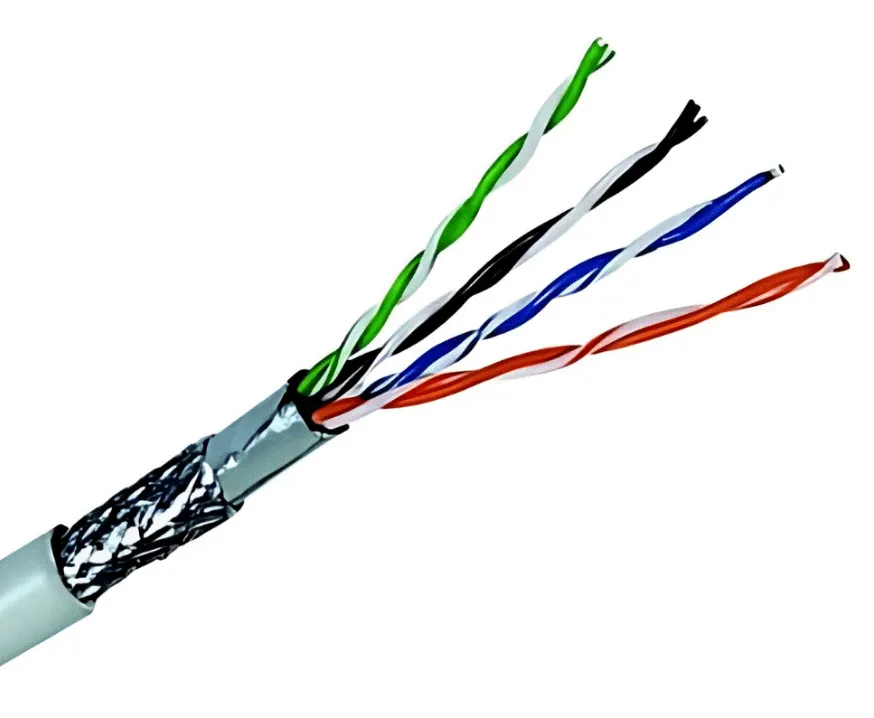

How to Tell Pure Copper from CCA

Since some manufacturers mislabel products, it’s important to verify what you’re buying:

- Check packaging for “solid bare copper” or “CCA”

- Request a product specification sheet

- Compare weight—copper feels noticeably heavier

- Inspect a cut sample—aluminum appears silvery, while copper is reddish

Purchasing from reputable suppliers helps ensure you get genuine materials.

Final Thoughts

Both cable types may serve similar purposes on the surface, but their internal construction leads to very different outcomes. Pure copper Ethernet cables consistently deliver better performance, higher reliability, and safer operation—especially in demanding or long-term installations. Although CCA cables may seem attractive due to their lower cost, the reduced lifespan and potential performance issues often outweigh the savings.

For any network you want to depend on, pure copper is the smarter and more future-proof investment.