Keeping a fiber optic network running smoothly requires the right tools for quick and accurate troubleshooting. One device that has become essential for both newcomers and experienced technicians is the Visual Fault Locator, commonly known as a VFL. This simple yet effective tool uses visible light to help identify common problems in fiber cables. In this guide, we’ll look at what a VFL is, how it works, the types available, and how to use it confidently in day-to-day maintenance.

Understanding What a Visual Fault Locator Does

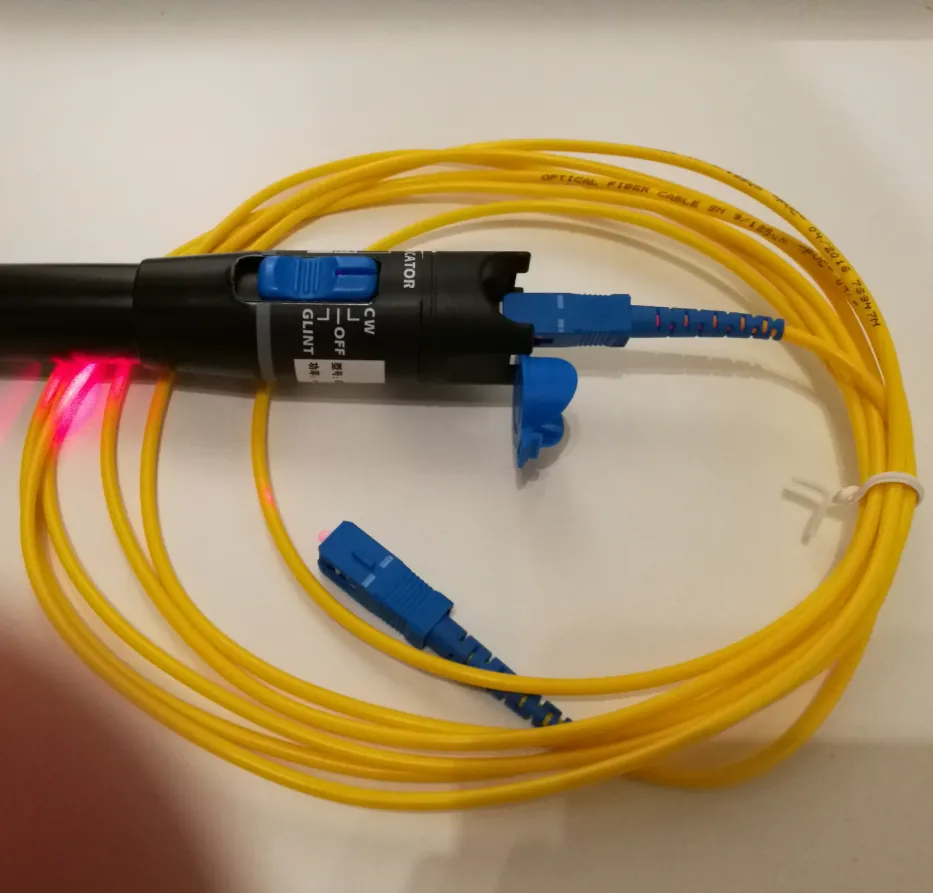

A Visual Fault Locator is a compact tool designed to spot issues in fiber optic cables by injecting a bright red laser into the fiber. When the cable has defects such as breaks, stress points, or poorly aligned splices, the light escapes at the damaged area. This makes problem spots easy to see, even without advanced testing equipment. Because it allows quick inspections, a VFL is a valuable first step in diagnosing connectivity issues.

How a VFL Works

Using a VFL is based on a simple principle. The tool sends a visible laser—usually around 650 nm—into the fiber core. The light moves along the fiber until it encounters an irregularity. At that point, the beam leaks out, highlighting the fault. Technicians can then visually track down the problem by following the red glow. While more sophisticated devices like OTDRs provide detailed measurements, a VFL is ideal for short links and straightforward fault detection.

Types of Visual Fault Locators

Two main styles of VFLs are commonly used:

Pen-Style VFL

This version resembles a thick pen and is easy to carry in a tool kit. It runs on batteries, making it convenient for quick checks and short cable runs.

Handheld or Gun-Style VFL

Larger and more powerful, this type delivers stronger output and can test longer distances. It is better suited for demanding installation and maintenance tasks where durability and performance matter.

Common Issues a VFL Can Reveal

Because the red laser is so visible, a VFL can detect several kinds of fiber problems:

Fiber Breaks

A complete break makes the light spill out clearly at the damaged spot.

Excessive Bends

Sharp bends or kinks allow light to leak, indicating areas where the cable is under stress.

Poor Splices or Damaged Connectors

If a splice isn’t aligned correctly or a connector is faulty, the escaping light highlights the issue.

Misaligned Connections

Connector interfaces that aren’t seated properly often leak light, signaling the need for cleaning or adjustment.

Benefits of Using a Visual Fault Locator

A VFL brings several advantages to fiber optic maintenance:

Fast Detection

It quickly isolates faults without requiring full-scale testing.

Affordable Tool

A VFL costs far less than advanced testing instruments, making it a practical choice for everyday troubleshooting.

Portable and User-Friendly

Most models are lightweight, straightforward to operate, and ideal for field technicians.

Reliable Maintenance Aid

Regular checks with a VFL help catch small issues early, improving overall network stability.

Versatile Use

VFLs work with both single-mode and multimode fibers, adding to their value in mixed installations.

How to Use a VFL Correctly

Operating a VFL is simple:

- Prepare the cable by cleaning the connector and removing dust caps.

- Connect the VFL to the fiber’s connector port.

- Turn on the device and select continuous or pulsed light mode.

- Trace the fiber and look for visible light leaks.

- Mark the fault location and perform necessary repairs.

- Test the fiber again to confirm that the issue is resolved.

Choosing the Right VFL

When selecting a VFL, consider:

Output Power

Higher-power models reach farther distances, while lower-power versions are suitable for routine checks.

Compatibility

Ensure it supports both single-mode and multimode fiber types.

Battery Performance

A long-lasting battery is essential for field work.

Durability

A rugged exterior helps the tool withstand tough environments.

Extra Features

Pulse modes or rechargeable batteries can improve usability.

Limitations to Be Aware Of

Although very helpful, a VFL has its constraints:

It is not ideal for long-distance tests.

It cannot measure optical loss or provide detailed analytics.

It only reveals faults where visible light escapes.

Despite these limitations, a VFL remains one of the most practical tools for quick inspections and basic diagnostics.

Conclusion

A Visual Fault Locator is an indispensable part of any fiber optic toolkit. It offers a fast and straightforward way to identify breaks, bends, and connection problems, helping technicians restore service quickly. Whether you’re learning fiber optics or maintaining large networks, understanding how to use a VFL effectively will greatly improve your troubleshooting capabilities and help ensure stable, high-quality network performance.