As communication networks continue to expand and demand for high-speed connectivity increases, the infrastructure that supports these systems becomes even more important. One key component of today’s telecommunications landscape is Outside Plant (OSP) fiber cable. Designed specifically for outdoor environments, OSP fiber forms the backbone of long-distance and high-capacity networks.

In this blog, we’ll explore what OSP fiber cable is, the different types available, where it’s used, and what goes into installing and maintaining it.

What Is OSP Fiber Cable?

OSP fiber cable refers to fiber optic cables engineered for outdoor deployment. Unlike indoor cables, these are built to endure harsh environmental conditions such as extreme temperatures, moisture, UV radiation, and physical strain. They are used to extend fiber networks across cities, rural areas, transportation routes, and industrial zones—essentially anywhere long-distance or outdoor connectivity is required.

Common Types of OSP Fiber Cable

Different environments and applications call for different cable designs. Some of the most widely used OSP fiber types include:

Aerial Fiber Cables

Mounted on poles or overhead structures

Built to handle wind stress, ice loading, and sunlight exposure

May be self-supporting or attached to a messenger wire

Direct-Buried Fiber Cables

Placed directly into the ground without conduit

Protected with rugged outer jackets to resist moisture, rodents, and soil pressure

Ideal for rural routes or areas without existing conduit systems

Duct Fiber Cables

Pulled through pre-installed conduits

Easier to replace or upgrade in the future

Common in urban networks with established utility ductwork

Submarine Fiber Cables

Installed under lakes, rivers, and oceans

Equipped with waterproof and pressure-resistant layers

Used for undersea communication links and offshore facilities

Armored Fiber Cables

Feature a metal or high-strength protection layer

Best for areas where digging, heavy equipment, or wildlife pose a threat

Where OSP Fiber Cables Are Used

OSP fiber is deployed across a diverse range of industries and infrastructure systems:

- Telecommunications: Connects central offices, towers, and backbone networks

- Internet Service Providers: Delivers broadband services to homes and businesses

- Smart Grid and Utilities: Supports automation and monitoring of electrical systems

- Government and Military: Ensures secure, long-distance communication

- Transportation: Used in highways, railways, and airports for communication and signaling

How OSP Fiber Cables Are Installed

Installing OSP fiber is a technical process that requires planning, specialized tools, and adherence to standards. Key stages include:

Planning and Surveying

Evaluate the installation route

Identify obstacles like roads, rivers, or buildings

Select the most suitable cable type and installation method

Secure permits and approvals

Cable Deployment

Aerial cables are mounted on poles and secured in place

Buried cables require trenching, plowing, or directional boring

Duct installations use pulling equipment and lubricants to feed fiber into conduits

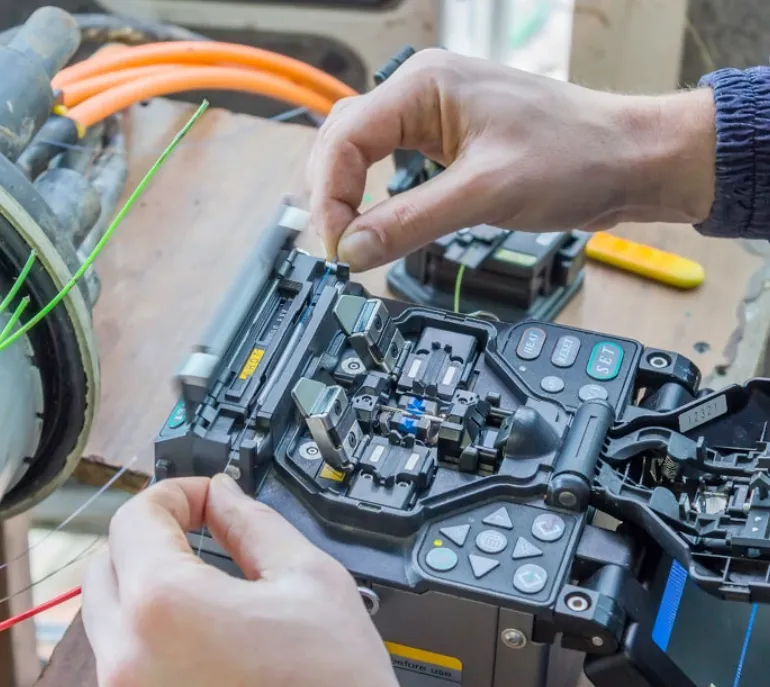

Splicing and Termination

Fiber ends are joined using fusion or mechanical splicing

Connectors are attached for integration with network equipment

Splice closures protect the joints from environmental damage

Testing the Network

Tools such as OTDRs and power meters verify fiber integrity

Technicians identify and correct attenuation issues or breaks

Network acceptance testing is completed before activation

Benefits of OSP Fiber Cable

OSP fiber offers numerous advantages that make it the preferred choice for outdoor networking:

- High bandwidth capacity for internet, TV, and cloud services

- Low signal loss, enabling long-distance data transmission

- Immunity to electromagnetic interference, ensuring stable performance

- Durability, even in severe weather and harsh environments

- Scalability, supporting future growth and higher data demands

Challenges of OSP Deployment

Although highly capable, OSP fiber projects often face challenges such as:

- High initial cost due to materials, labor, and construction

- Complex installations requiring skilled crews

- Regulatory hurdles and right-of-way negotiations

- Difficult access for repairing buried or underwater cables

Maintaining OSP Fiber Networks

Proper maintenance ensures long-term reliability and performance:

Routine Inspections

Monitor cable routes for damage caused by storms, animals, or construction

Check poles and aerial hardware for wear or sagging

Testing the Fiber

Use OTDR to pinpoint faults or signal degradation

Perform attenuation checks to ensure quality

Emergency Repairs

Locate breaks quickly to restore service

Use protective closures to safeguard repaired sections

Upgrades and Expansion

Increase capacity by adding new fibers or replacing aging segments

Update equipment to support higher bandwidth requirements

Final Thoughts

OSP fiber cable is a foundational element of modern communication networks. Its rugged construction, high performance, and ability to cover long distances make it indispensable for telecom carriers, utilities, and large-scale infrastructure projects. While installation and upkeep can be complex, the long-term benefits—speed, reliability, and scalability—far outweigh the challenges.

As the world moves toward faster and more connected systems, OSP fiber will continue to play a central role in delivering high-performance communication across communities and industries.