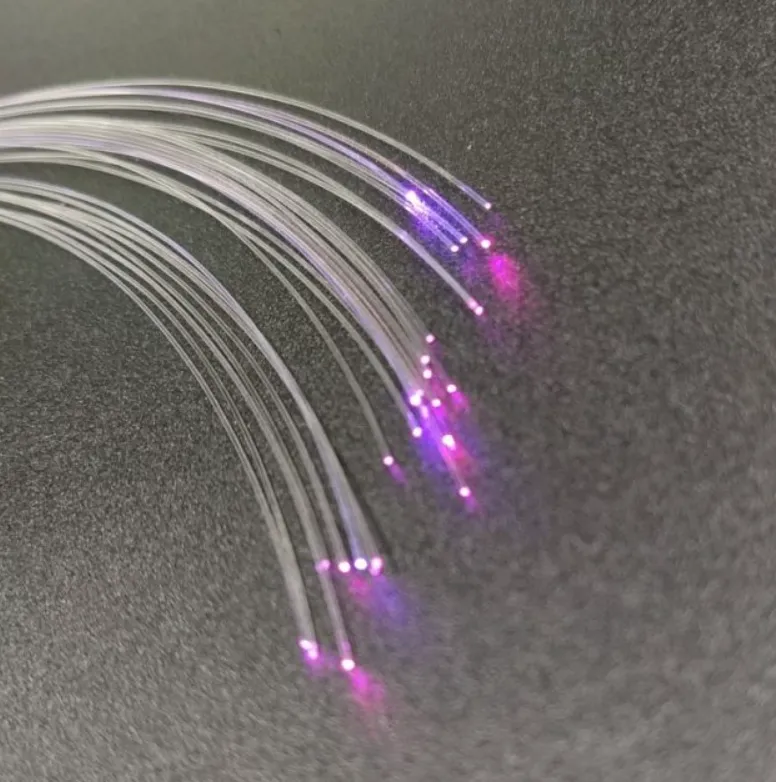

In the fast-paced world of fiber optics, bare optical fibers serve a crucial purpose across research, testing, and specialized engineering applications. Unlike standard fiber cables that come with multiple protective layers, bare fibers expose the glass core and cladding, making them versatile for customization yet delicate to handle. Whether you’re in telecommunications, laboratory research, or industrial sensing, understanding the key factors before buying bare fibers can save you both time and money.

This article explores the most important considerations when purchasing bare optical fibers, including their specifications, handling requirements, and quality factors that ensure performance and reliability.

Understanding Bare Optical Fiber Specifications

Before purchasing, it’s essential to understand how different characteristics of bare optical fibers affect their performance. Because these fibers lack external protection, the material and design specifications are critical for achieving the desired optical results.

Core and Cladding Dimensions

Bare optical fibers are primarily defined by their core and cladding diameters. The core transmits the light signal, while the cladding maintains total internal reflection.

- Single-mode fibers typically have a core size of 8–10 microns, optimized for long-distance transmission with minimal signal loss.

- Multimode fibers have larger cores—usually 50 or 62.5 microns—ideal for shorter distances and higher bandwidth applications.

The cladding is usually standardized at 125 microns, but verifying compatibility with your connectors and splicing tools is still necessary.

Operating Wavelength

Different fiber types are optimized for specific wavelengths:

- 850 nm for short-range data center links (multimode).

- 1310 nm for low dispersion.

- 1550 nm for the lowest attenuation across long distances.

Selecting a fiber that supports your intended wavelength ensures better efficiency and minimal transmission loss.

Numerical Aperture (NA)

The numerical aperture determines how much light the fiber can capture and transmit. A higher NA is useful for illumination or sensing, while a lower NA provides higher precision and stability for communication systems.

Coating and Buffer Options

Even “bare” fibers are often coated with thin protective layers to improve durability:

- Acrylate coatings for standard telecom and indoor use.

- Polyimide coatings for high-temperature or aerospace environments.

- Carbon coatings for moisture resistance and reduced micro-bending losses.

Choosing the right coating enhances performance and lifespan under specific operating conditions.

Handling and Practical Considerations

Because bare fibers are fragile, their handling, storage, and packaging require special care. Proper practices ensure that you get accurate results and avoid costly damage.

Fragility and Handling

Bare fibers are susceptible to breakage and contamination. Always handle them using fiber holders or tweezers, avoid tight bends, and keep workspaces clean to prevent dust from affecting the glass surface. Training in fiber splicing and termination is recommended for those new to handling bare fibers.

Packaging and Delivery Format

Bare optical fibers are available in different configurations, depending on your use case:

- Reels or spools for research and prototyping.

- Pre-cut lengths for controlled lab experiments.

- Pre-terminated assemblies for easy integration into existing systems.

Ensure that packaging provides adequate protection during transport, as even microscopic cracks can increase signal loss.

Supplier Quality and Certification

Working with a reputable supplier is vital. Look for vendors who provide:

- Compliance with ISO quality standards.

- Detailed test data for attenuation and bandwidth.

- Technical support for selection and usage.

While cheaper options might be tempting, low-quality fibers often result in poor optical performance or short operational lifespans.

Balancing Cost and Application Requirements

Prices can vary greatly depending on fiber type, coating, and intended use. For instance, research projects may only require small quantities of cost-effective fibers, while telecommunications networks demand premium-grade options with proven reliability. Always align your purchase with the technical and financial scope of your project.

Applications of Bare Optical Fibers

Bare optical fibers are indispensable in a wide range of industries:

- Telecommunications: Used in high-speed internet and long-haul data transmission.

- Medical Imaging: Essential for endoscopy and laser delivery systems.

- Sensing: Employed in temperature, strain, and pressure detection systems.

- Research and Development: Used in experimental optical setups and prototype testing.

- Aerospace and Defense: High-performance fibers with advanced coatings for extreme environments.

The Future of Bare Optical Fiber Technology

Innovations in bare fiber design are making them stronger and more versatile. Developments include:

- Nanostructured coatings to enhance flexibility and durability.

- Hybrid fibers that support multiple transmission modes.

- Ruggedized designs resistant to environmental stress and humidity.

As industries continue to embrace 5G, AI, and smart infrastructure, demand for high-quality bare fibers will only increase.

Conclusion

Bare optical fibers remain fundamental to modern communications, scientific research, and specialized sensing applications. When buying them, it’s essential to evaluate both technical parameters—such as core size, wavelength range, and coating—and practical aspects, including supplier reputation and handling requirements. By understanding these key factors, you can make an informed purchase that ensures performance, durability, and long-term value.

Investing wisely in the right bare optical fiber today sets the stage for dependable innovation and connectivity tomorrow.